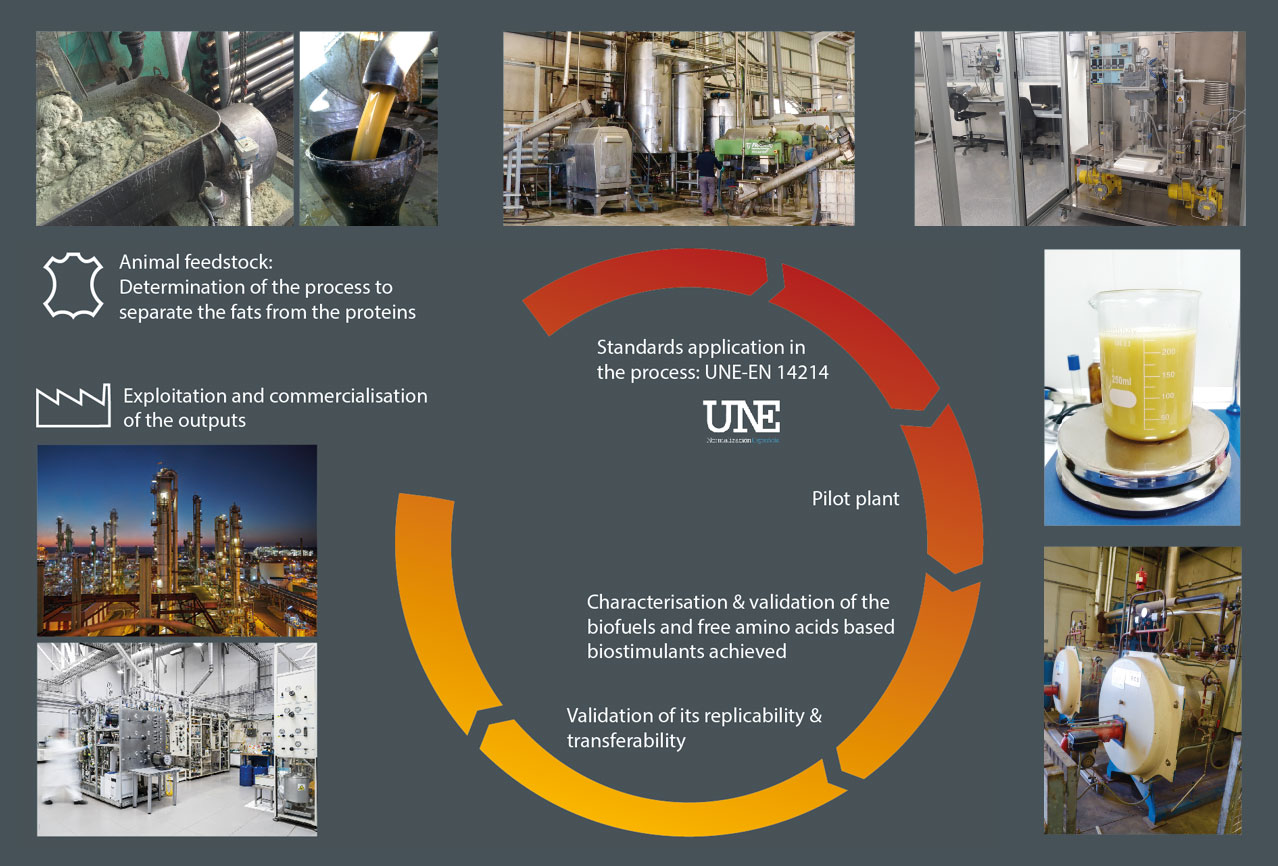

The overall aim of this project is to apply an improved process, sustainable and ecological to obtain an eco-efficient biodiesel in accordance with current directives and regulations, from raw material from animal waste, thus applying the principles of circular economy.

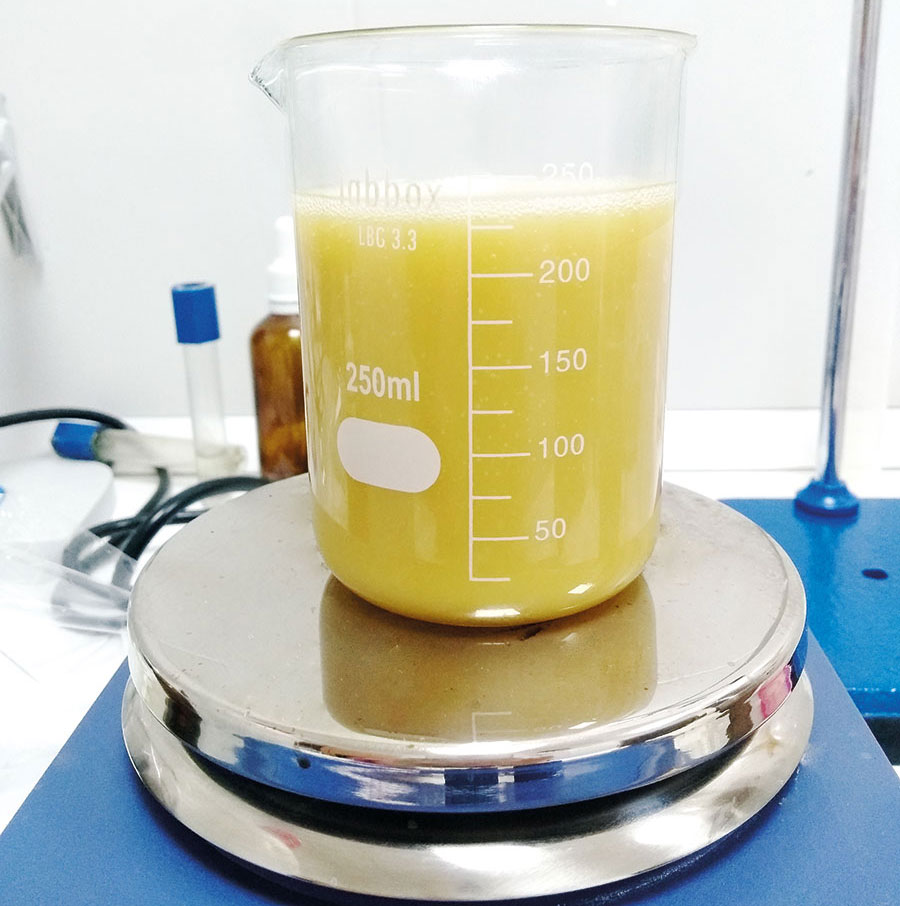

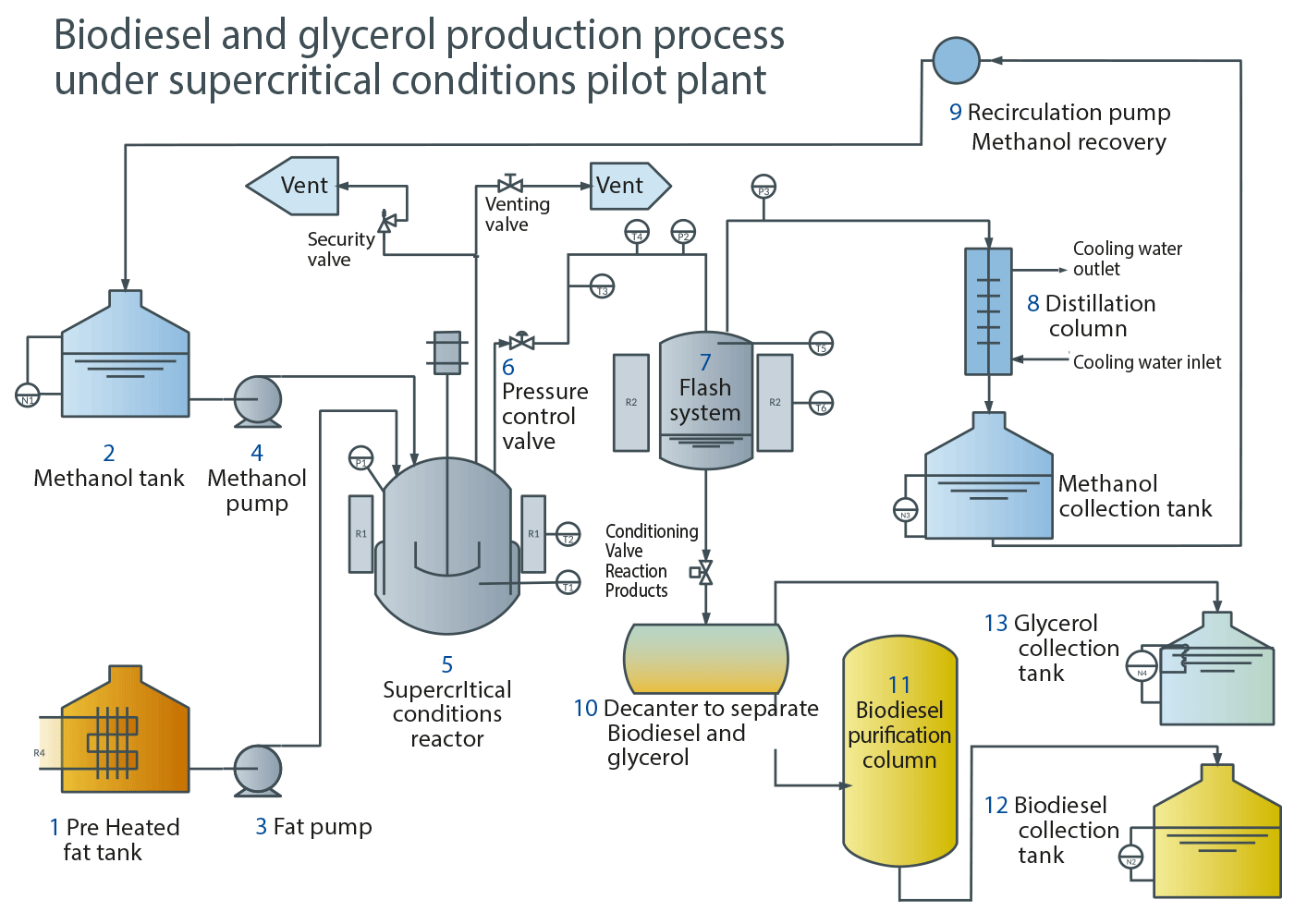

To achieve the foreseen aim, the project will determine the process to separate the fats from the proteins, will ensure the raw material quality standards for their application in the process and will design, construct and optimise a pilot plant to process 5 tons per year. The resultant products will be characterised and validated, the replicability and transferability of the process corroborated, and the outputs exploited and commercialised.